Bag Conversion Line

Fully Automatic Bag Conversion Line

The New generation bag conversion line ABCS.850 series is specifically designed for coated or uncoated standard fabric, leno fabric and BOPP laminated fabrics.

High productivity coupled with flexibility is the hall mark of the machine. The machine has a capacity to produce 40 to 50 bags per minute with optimal material saving for maximum financial gains.

Highlights Standard Features

Productivity Information

| Sr. No. | DISCRIPTION | SPECIFICATION |

| 1 | WIDTH OF UNWINDING FABRIC ROLL | 300 TO 850 mm |

| 2 | DIAMETER OF FABRIC ROLL | 1250 mm |

| 3 | INTERNAL DIAMETER OF FABRIC ROLL CORE | 70 TO 115 mm |

| 4 | REPLACEMENT OF FABRIC ROLL | Pneumatic System |

| 5 | Cutting Length | 600 to 1350 mm |

| 6 | Bottom Folding Width | 16 to 30 mm (Adjustable(For Single Fold) |

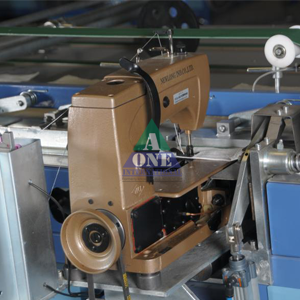

| 7 | Stitching Type | Single STITCH / Doubel Stitch |

| 8 | Stitcthinh Range | 5 to 10 mm |

| 9 | Production Speed | 25 to 40 bags / Minte* |

| 10. | Dimensions (L X B X H) | 17 X 17 X 6 feet |

*Depends on material used, width of fabric, no. of folds and stitches, etc Special Features: You can take production of 1.75 gram natural fabric Optional Features