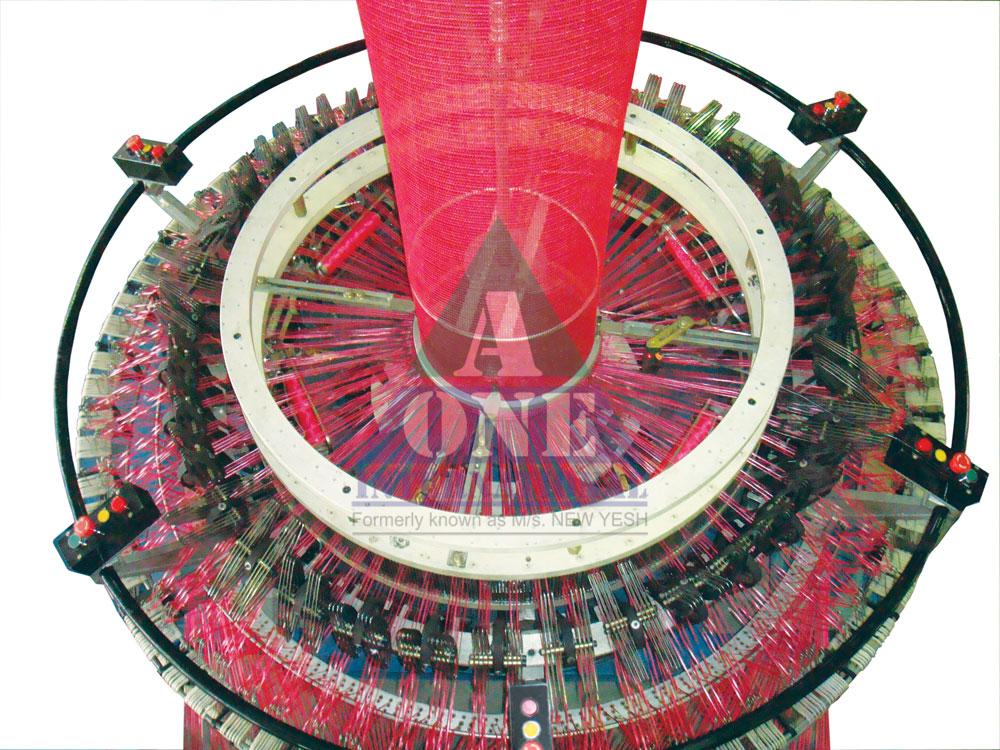

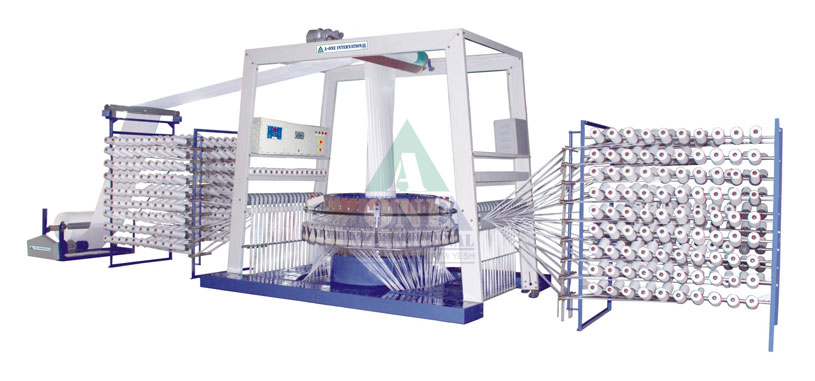

Circular Looms

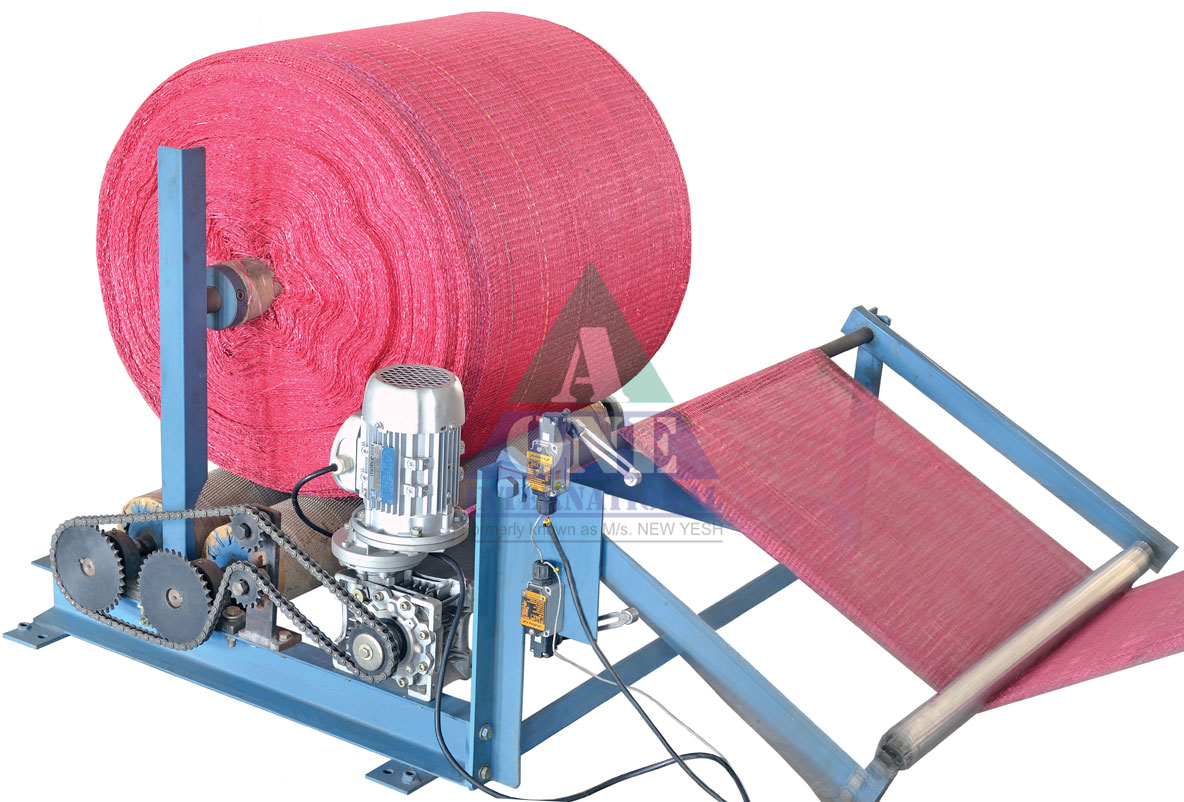

For years, through constant research and improvements, we present to you a great variety of plastic fabricating system. Higher operating efficiencies, excellent weaving quality, lower wastage, lower energy consumption, lower maintenance etc. Making our looms, the best choice for customers.

SALIENT FEATURES

APPLICATIONS

MODELS

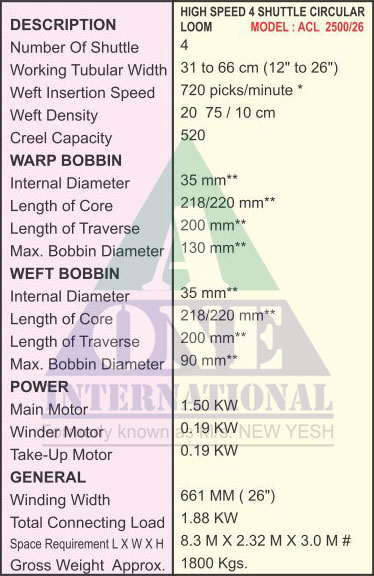

- ACL 2500 - 24 : High Speed 4 Shuttle

Circular Loom, which is especially meant for Cement bags as well

as Fertilizer Bags and also offers various benefits in terms of

output, power saving & spares consumption etc. This Loom can

run with 2 HP main Motor. You can weave 8" to 24"

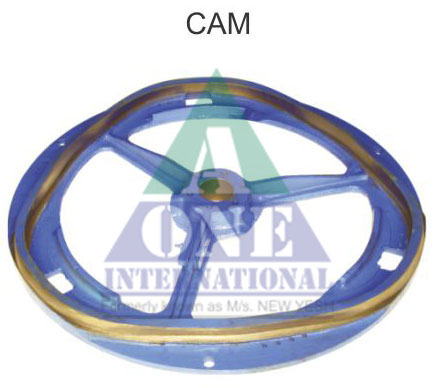

fabric. A FLAT CAM STRUCTURE WITH HIGH OUTPUT, HIGH EFFICIENCY,

LOWER ELECTRICAL CONSUMPTION & LOW MAINTENANCE.

With Newly developed cam design, our 4-Shuttle circular looms can achieve the energy, economy and greatly meters. These are equipped with automatic stopping devices to detect warp or weft breakage and monitoring through sensors.The small size 4 shuttle looms can weave tubular cloth from 12” to26”

-

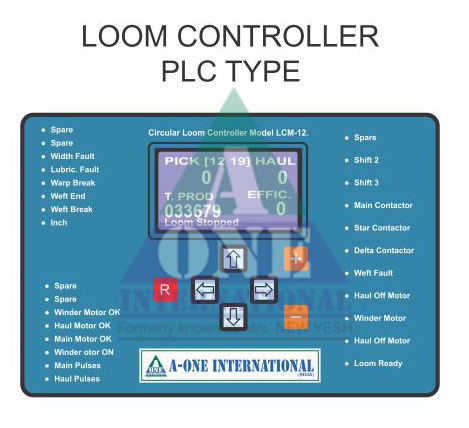

- CONTROL PANEL The latest HMI equipped, contain of all function program as:

- All the motor switch and overload indication.

- Insertion speed regulation through frequency inverter.

- Shuttle's lubricating pump timing control.

- Producing counter (3 shifts)

- Warp and weft datector comtrol system

- Weft density setting

- The latest HMI equipped, contain of all function program as:

- All the motor switch and overload indication.

- Insertion speed regulation through frequency inverter.

- Shuttle's lubricating pump timing control.

- Producing counter (3 shifts)

- Warp and weft datector comtrol system

- Weft density setting

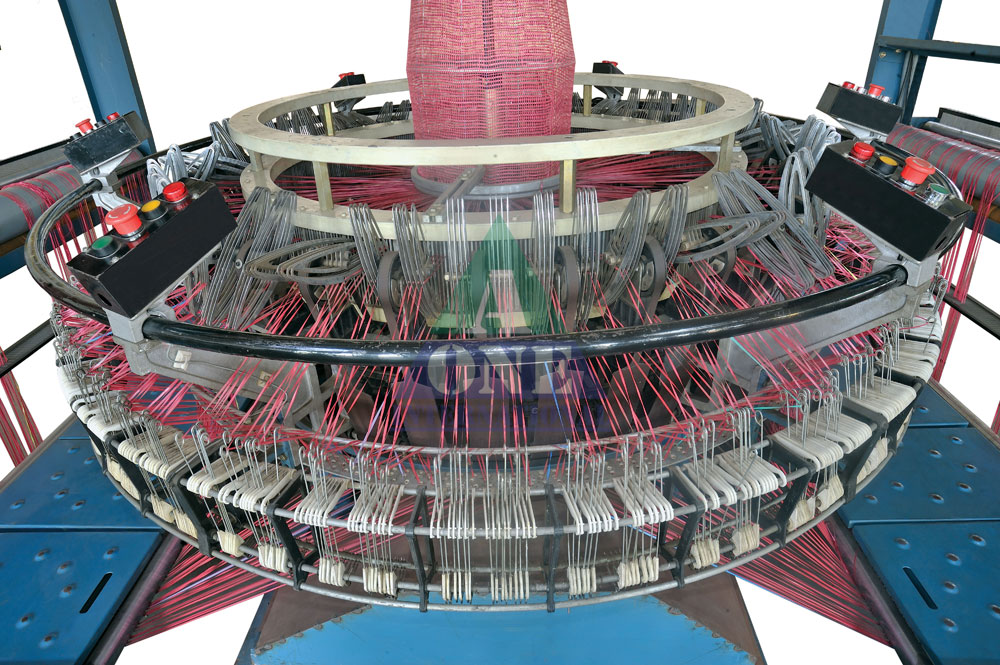

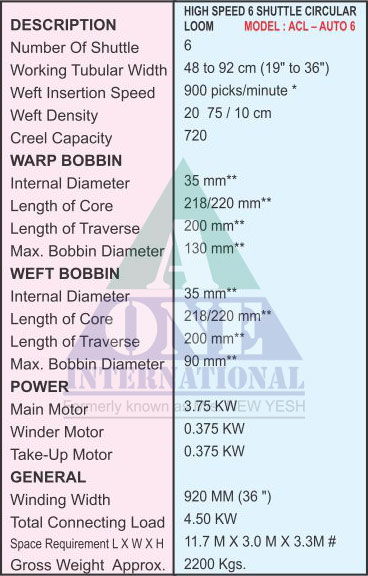

EIGHT SHUTTLE LOOMS

High Speed Six and Eight Shuttles Circular Loom is designed for making la rge size plastic woven bags,it is the ideal machine for making Flexible Intermediate Bulk Containers,Tarpaulins,waterproof cloth and so on with PE,PP and synthetic tape.This machine is featu red in advanced technology,reasonable structu re,smooth operation,easy to maintain and control,and it is equipped with the highly automatic ala rming and autostop device for wa rps offor over situation,moreover it is frequency controllable.

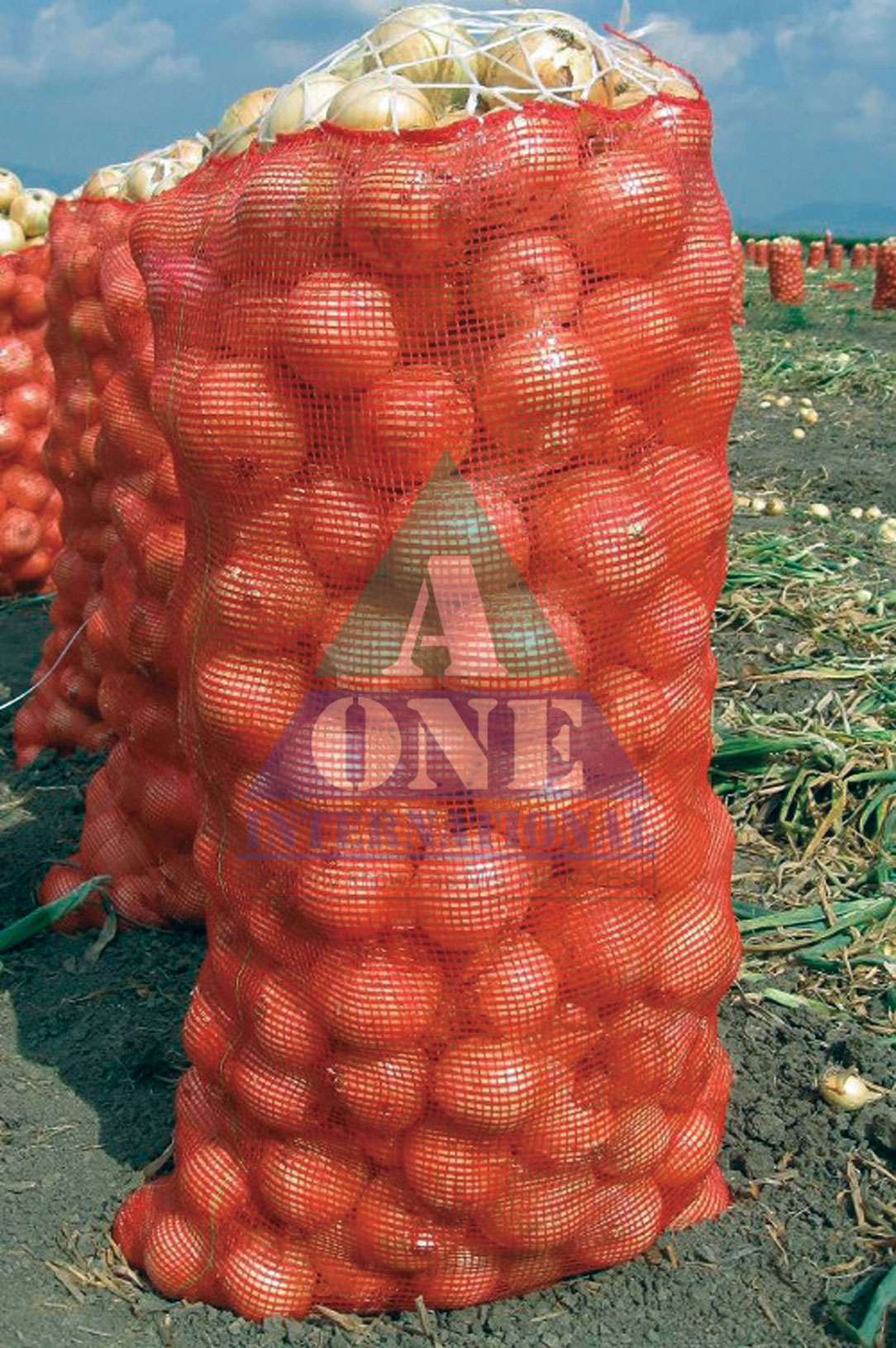

- ACL Leno4/ Leno6

Leno4/ Leno6 4/6 shuttle loom provides the ideal solution for producing high quality open mesh (leno weave) fabric for the packaging of perishables.

Circular woven leno sacks for fruits and vegetables – another product concept developed by A ONE INTERNATIONAL which went on to become a worldwide standard. The smooth surface of the open mesh leno fabric protects the delicate surface of the fruits. Combines the advantages of standard and leno weave in a single sack concept: The leno plus sack is an open mesh weave for maximum breathability, with a closed weave section allowing printing in top quality for a new type of high grade leno bag.

ADVANTAGESOil-free fabric for food-safe products*

• Best weaving quality

• Low energy consumption

• Low maintenance costs Wear and tear resistant

• Operator friendly design