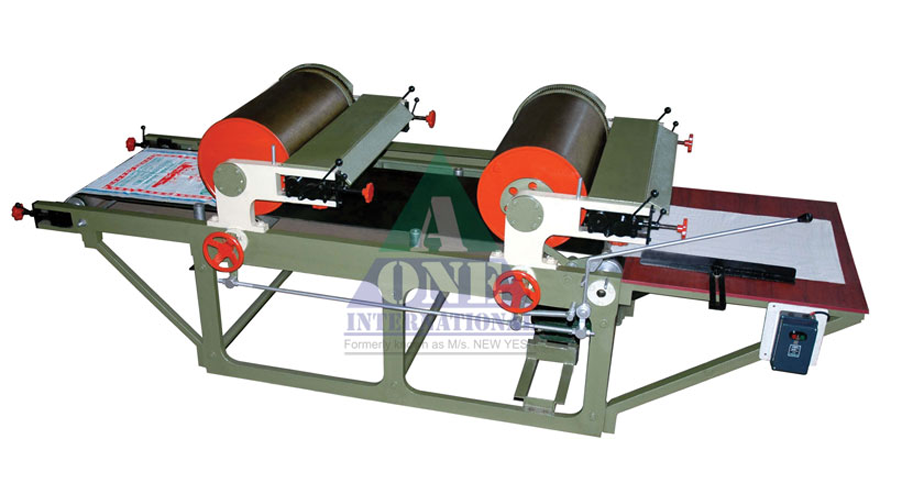

Flexo Graphic Printing

Straightforward application and excellent process reliability makes flexographic printing the most widely used process in printing of:

- HDPE/PP Woven Bags,

- Flour sacks and Cement & Fertilizer bags

- Non-Woven Sacks/Bags

- Jumbo Bag/ FIBC

- Multiwall Paper Sacks

- Corrugated Sheets

The results now achieved with flexographic printing also satisfy high quality requirements and are extremely cost-effective.

Our mission is to deliver highly innovative solutions for the flexographic printing industry.

We strive to save costs, increase efficiency and quality for our customers. We rely on our experience in FLEXOGRAPHIC PRINTING MACHINE, and automating as well as digitalizing traditional workflows.

APPLICATION

FEATURES :

ADDITIONAL ACCESSORIES :

×